YUEYI Mold, China top co injection mold maker, quality offer two color stack mold, multi shot stack molding, double-deck injection mold 2k, plastic double multiple mold!

Thanks to the previous failure experience, now we’re very familiar with the production of stack molds.

And stack mold technology allows for the creation of the right plastics solution, using it in combination with any other applicable technologies that are part of Focare’s offerings:

- multi material,

- collapsible cores,

- unscrewing demoulding

- also in mold functions such as in mold closing for two color flip top caps

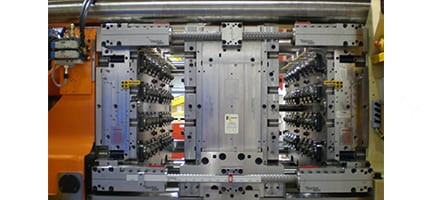

Two color stack molds to increase productivity of each injection molding machine

Two color stack mold designs have evolved to successfully fill the needs of a wide variety of injection molding plastic applications. As the need for high production volumes are climbing, there may never have been a better time to review the present-day features and capabilities of stack mold technology.

If you’re still looking for the multi shot stack mold maker in China, we Focare can be your only choice!

Lucia

lucia@yueyimold.com