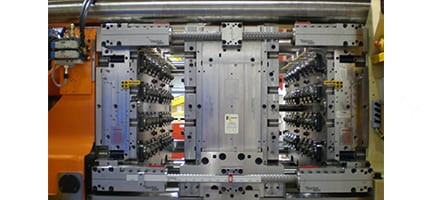

YUEYI Mold, China experienced 2 component mold maker, quality offer multi shot flip tops mold, bicolors compression snap caps mold, double screw flip cap plastic bottle mold, bi injection bottle cap butterfly lid mold.

When a traditional rotary die machine cannot meet output, you can start to consider using a rotary die (cubic die). Here is an example of bottle caps with an annual sales volume of approximately 45 million. When output continues to rise, it may cause a sharp increase in production costs, because this in turn will be related to number of machines required. Rotary mold (cubic mold) technology is ideal for mass production play an important role in utilization. The higher utilization of this system combination, the more economical this technology may be compared to other technologies. In mass production, use of rotating molds (cubic molds) can achieve purpose of significantly reducing production costs. This will result in a situation where fewer machines are needed and/or cycle times can be significantly reduced. As a rough guide, it can be said that for parts with a cycle time greater than 10 seconds and corresponding sales requirements, this is worth considering and does not limit industry.

If you’re still looking for the good two color flip cap seals mold maker in China, we can be your another good choice.

Lucia

lucia@yueyimold.com